|

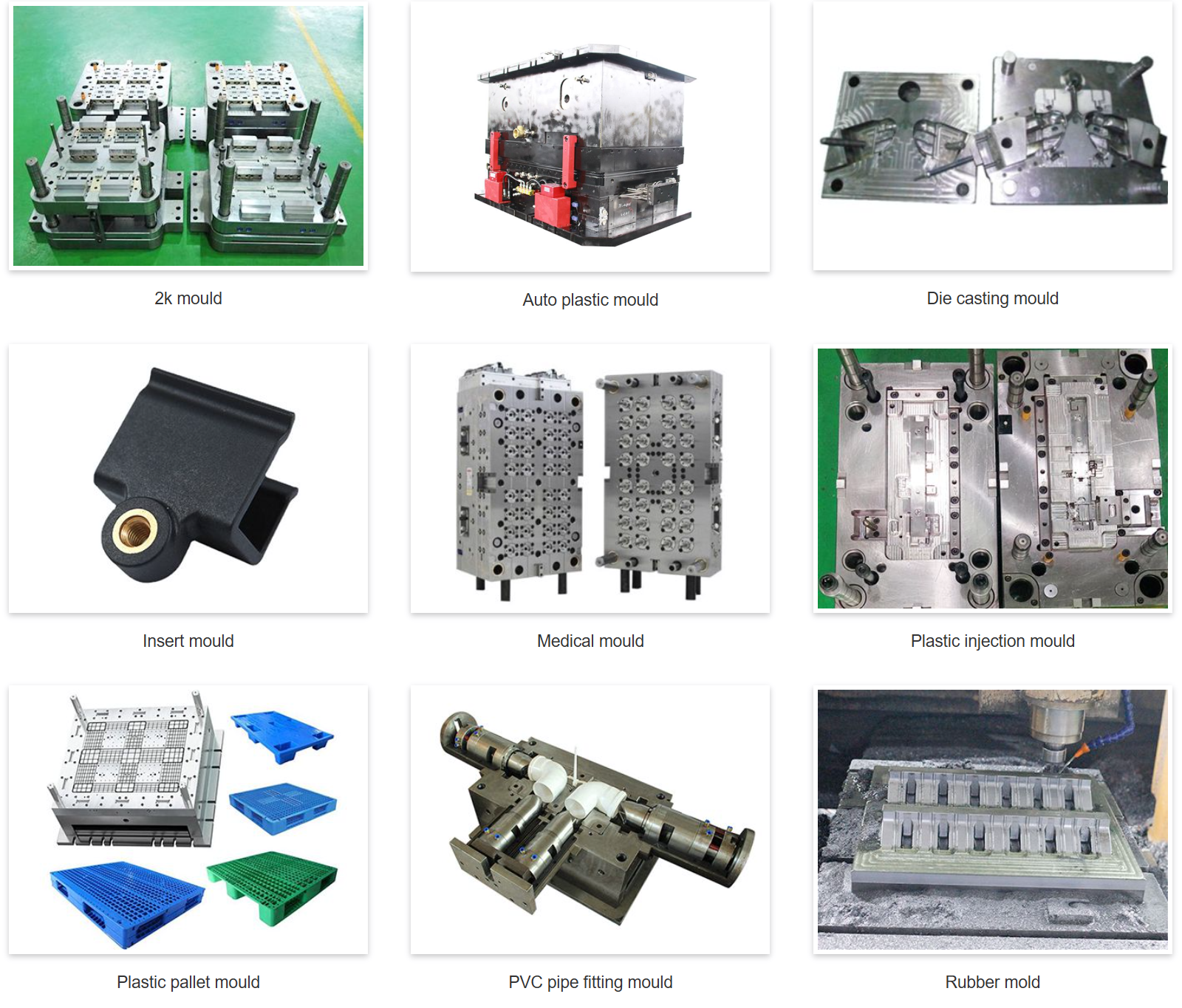

Mould design and manufacturingTianlong Precision: Your Expert Partner in Product Development & Precision Tooling. Our skilled design and engineering team possesses the tools, talent, and experience to:

Precision Tooling Expertise: Our experienced toolmakers excel at creating highly complex molds with demanding tolerances. Commitment to Excellence: Customer satisfaction drives our strict quality standards. We leverage modern facilities, dynamic equipment, and a skilled workforce dedicated to ingenuity and superb results. Tianlong Precision Offers:

Mould Types we can fabricate: Tianlong Precision Mold Co.,Ltd Industry ExpertiseWe deliver high-precision molds for:

Core Mold Technologies

Product Application Portfolio

Commitment to Excellence Your Vision • Our Precision • Global Standards

Tianlong Precision purchase mould steel material and standard components from the qualified mould steel and components suppliers Mould Steel suppliers: LKM; ASSAB; THYSSEN; DAIDO; FINKL and Gröditzer,etc. Mold base suppliers: LKM, FUTABA, HASCO, DME, etc. Hot runner suppliers: Synventive; Mold-Masters; HRS; HUSKY; YUDO;Incoe;EWIKON; etc. Standard components suppliers: HASCO; DME; LKM; MISUMI; CUMSA; MEUSBURGER etc. Hydraulic cylinder suppliers: HPS; PARKER; VEGA and MERKLE etc. Texture suppliers:Mold-Tech, YICK SANG, etc. The software that we are using: Pro/Engineer (3D Modeling) SolidWorks (3D Modeling) Catia (3D Modeling) Unigraphics (3D Modeling & CNC Programming) AutoCad (2D Modeling) MoldFlow Analyze MasterCaM (CNC Programming) |