|

In depth market survey of China's mold industry in 2024

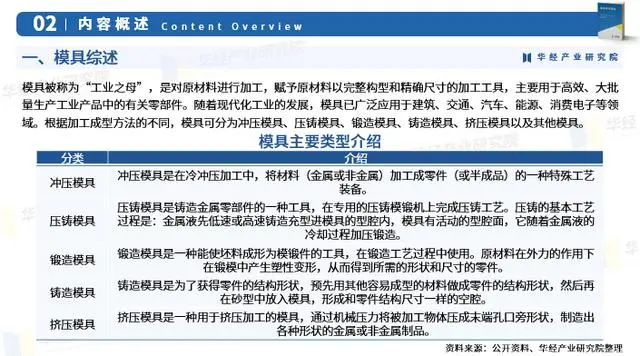

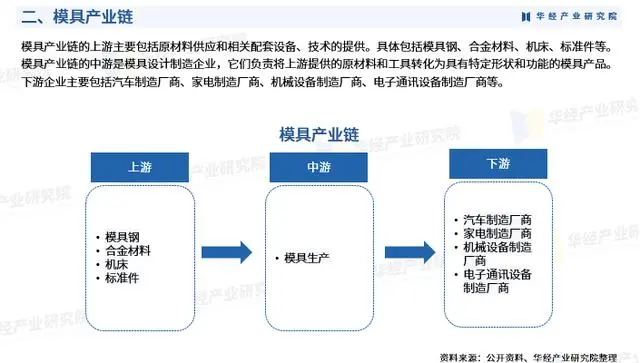

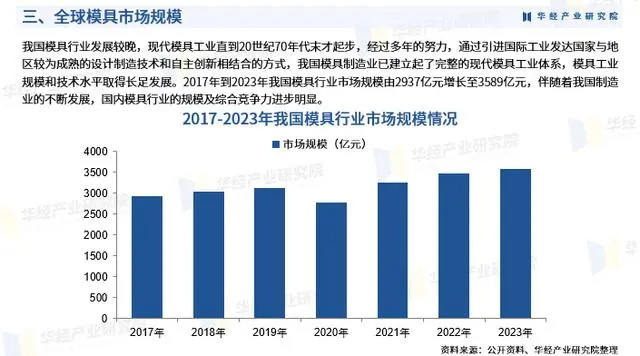

Mold is known as the "mother of industry" and is a processing tool that processes raw materials, endowing them with complete configurations and precise dimensions. It is mainly used for efficient and large-scale production of related components in industrial products. With the development of modern industry, molds have been widely used in fields such as construction, transportation, automobiles, energy, and consumer electronics. According to different processing and forming methods, molds can be divided into stamping molds, die-casting molds, forging molds, casting molds, extrusion molds, and other molds. The upstream of the mold industry chain mainly includes the supply of raw materials and the provision of related supporting equipment and technology. Specifically, it includes mold steel, alloy materials, machine tools, standard parts, etc. The midstream of the mold industry chain are mold design and manufacturing enterprises, which are responsible for transforming the raw materials and tools provided by the upstream into mold products with specific shapes and functions. Downstream enterprises mainly include automobile manufacturers, home appliance manufacturers, mechanical equipment manufacturers, electronic communication equipment manufacturers, etc. The development of China's mold industry was relatively late, and the modern mold industry did not start until the late 1970s. After years of efforts, by introducing mature design and manufacturing technologies from internationally developed countries and regions and combining independent innovation, China's mold manufacturing industry has established a complete modern mold industry system, and the scale and technological level of the mold industry have made significant progress. From 2017 to 2023, the market size of China's mold industry has increased from 293.7 billion yuan to 358.9 billion yuan. With the continuous development of China's manufacturing industry, the scale and comprehensive competitiveness of the domestic mold industry have made significant progress.

|