|

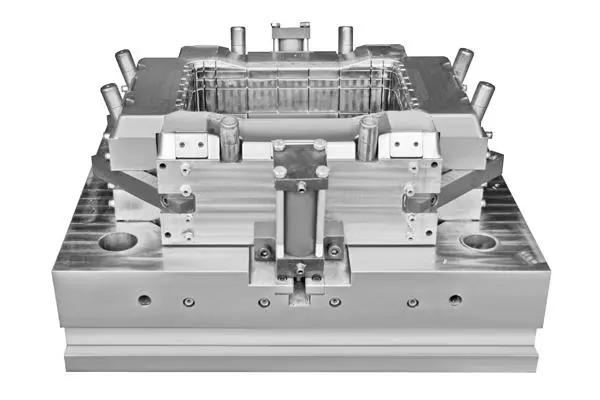

Maintenance and upkeep of molds

1: After long-term use of the mold, the cutting edge must be ground, and the cutting edge surface must be demagnetized to avoid magnetism, otherwise it is prone to material blockage. Mold using enterprises should make detailed records and statistics on their use, care (lubrication, cleaning, rust prevention), and damage situation. Based on this, they can discover which parts and components have been damaged, the degree of wear, and provide information and data for discovering and solving problems, as well as the molding process parameters of the mold and the materials used in the product, in order to shorten the mold testing time and improve production efficiency. The various properties of the injection molding machine and mold should be tested under normal operation, and the dimensions of the final formed plastic parts should be measured. Through this information, the existing state of the mold can be determined, and the damage to the cavity, core, cooling system, and parting surface can be identified. Based on the information provided by the plastic parts, the damage status of the mold and maintenance measures can be determined. 2: Elastic components such as springs are most susceptible to damage during use, often resulting in breakage and deformation. The method adopted is replacement. During the replacement process, it is necessary to pay attention to the specifications and models of the spring. The specifications and models of the spring are confirmed by three items: color, outer diameter, and length. Only when all three items are the same can it be replaced. Imported quality is preferred for springs. 3: During the use of molds, the punch is prone to breakage, bending, and gnawing, and the punching sleeve is generally gnawed. The damage to the punch and punch sleeve is usually replaced with parts of the same specifications. The parameters of the punch mainly include the working part size, installation part size, length size, etc. 4: Tighten the parts and check if they are loose or damaged. The solution is to replace them with parts of the same specifications. 5: Pressing parts such as pressing plates, Yuli glue, etc., unloading parts such as stripping plates, pneumatic top material, etc. During maintenance, check the relationship between the accessories in each part and whether there is any damage. Repair the damaged parts, check for air leakage in the pneumatic top material, and take measures for specific situations. Replace if the trachea is damaged. Key tracking and inspection should be carried out on several important components of the mold: the role of the ejector and guide parts is to ensure the opening and closing movement of the mold and the ejection of the plastic parts. If any part of them gets stuck due to damage, it will lead to production stoppage. Therefore, the lubrication of the mold ejector pin and guide post should be regularly maintained (the most suitable lubricant should be selected), and the ejector pin, guide post, etc. should be checked regularly for deformation and surface damage. Once discovered, they should be replaced in a timely manner; After completing a production cycle, professional rust proof oil should be applied to the working surface, motion, and guiding components of the mold. Special attention should be paid to protecting the bearing parts of the mold with gears and racks, as well as the elastic strength of the spring mold, to ensure that they are always in the best working condition; As production time continues, the cooling channel is prone to sedimentation of scale, rust, sludge, and algae, which reduces the cross-sectional area of the cooling channel and narrows it, greatly reducing the heat exchange rate between the coolant and the mold and increasing the production cost of the enterprise. Therefore, the cleaning of the channel should be taken seriously; For hot runner molds, maintenance of the heating and control system is particularly important in preventing production failures. |